In a process automation expansion, it is often specialist project resources that specify the new project and a specialist system integrator that programs the process automation platform. It is usually the operations department however that will have the most day to day contact with the control system. Thus it is the operations department that are the ultimate clients of the system and often the department that witness the factory acceptance testing.

The operations department are most interested in end-user usability and so are particularly interested in the HMI interface and graphics.

In addition, they can have expert insight into how the plant currently works, and can often quickly pick up on design discrepancies.

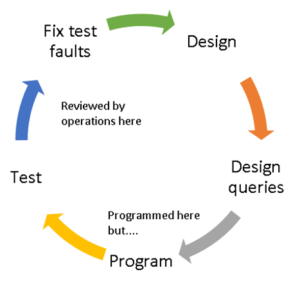

Unfortunately the imparting of this insight from operations to the project happens often at the factory acceptance test, as this is the first time they get to see the system in operation! However, at this point, all the software is programmed so a level of rework may result.

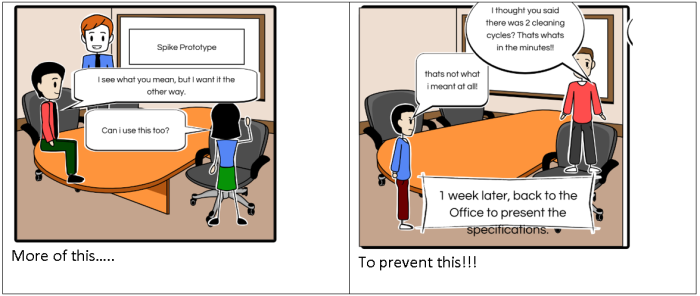

This mis-timing happens because there is nothing to interact with or visualise until the target system is actually programmed. Modern website development solves this problem through the use of prototyping and mock up sites (for example: https://moqups.com/).

Even if the target control system HMI cannot be easily ‘mocked up’ in a prototype, there is value in capturing the operation team requirements into the project requirements. And this should be done before design specification requirements are signed off. Earlier collaboration promotes better front end engineering design (FEED).

See Spike in action or try it yourself, no sign up or login required.